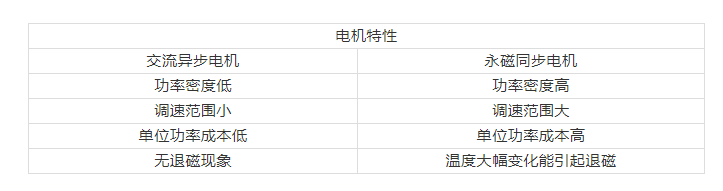

In the power system, you often hear the term permanent magnet synchronous motors and AC asynchronous motors, and in terms of frequency, permanent magnet synchronous motors occupy the vast majority. What is the difference between them, and what are their advantages and disadvantages?

Permanent magnet synchronous motor VS AC asynchronous motor

Compared with AC asynchronous motors, permanent magnet synchronous motors have the following advantages:

1. High efficiency, which can be explained from the following aspects

01 Since the magnetic field of the permanent magnet synchronous motor is generated by permanent magnets, the excitation loss caused by the magnetic field generated by the excitation current is avoided.

02 Compared with asynchronous motor, the external characteristic efficiency curve of permanent magnet synchronous motor has a higher efficiency value at light load. Compared with asynchronous motor, this is the biggest advantage of permanent magnet synchronous motor in terms of energy saving.

Generally, when a motor drives a load, it seldom runs at full power. This is because:

On the one hand, the user usually determines the motor power according to the extreme working conditions of the load when selecting the motor, and the chance of extreme working conditions is very small. At the same time, to prevent the motor from burning under asynchronous conditions, the user will also leave a certain amount of motor power margin.

On the other hand, when the designer designs the motor, in order to ensure the reliability of the motor, the user usually needs a certain power margin on this basis, so more than 90% of the actual operating motor has a low operating power 70% of the rated power, especially for motors driving fans or pumps. This causes the motor to usually work in a lightly loaded area.

For induction motors, their efficiency is very low under light loads, while permanent magnet synchronous motors can still maintain high efficiency under light loads.

03Due to the high power factor of the permanent magnet synchronous motor, its current is smaller than that of the asynchronous motor. Therefore, the stator copper loss of the motor is small and the efficiency is high.

04 High system efficiency. The parameters of the permanent magnet motor, especially the power factor, are not affected by the number of motor poles, so it is easy to design a multi-pole motor, so that the traditional load motor that needs to be driven by the gearbox can be turned into a permanent magnet synchronous motor, and a direct drive system driven by the motor The gearbox is omitted and the transmission efficiency is improved.

2. High power factor: The power factor of the permanent magnet synchronous motor can be adjusted during design, and it can even be designed to be 1, regardless of the number of poles of the motor. However, due to its own excitation characteristics, the asynchronous motor will increase with the number of poles. Increasing and increasing will inevitably lead to a decrease in power factor. For example, an 8-pole motor has a power factor of about 0.85. A motor with a high power factor has the following advantages:

01 High power factor, low motor current, reduce copper consumption of motor stator, more energy saving

02The power factor is high, the power capacity of the motor can be reduced, and other auxiliary facilities such as switches and cables can be smaller, and the corresponding cost is lower

03The power factor of the permanent magnet synchronous motor is not affected by the number of poles of the motor. If the motor support system allows, the number of poles of the motor can be designed to be more, the corresponding motor volume is smaller, and the direct material cost of the motor is lower .

3. Simple and flexible structure: Since the parameters of the permanent magnet synchronous motor are not affected by the number of poles of the motor, it is convenient to realize the direct drive of the load by the motor, and the gearbox with high noise and high failure rate is eliminated.

- Previous Article : Do you know the difference between stepper motor and servo motor?

- Next Article : No Record